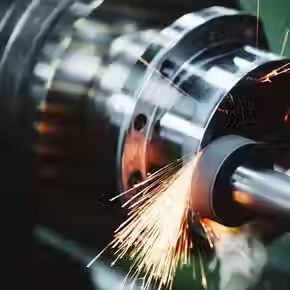

At A&G Price Ltd, we pride ourselves on delivering precision-engineered solutions through our robust capabilities in heavy industrial steel and aluminium fabrication. Our expansive 1600m² fabrication workshop, boasting a 20-tonne lifting capacity, is perfectly designed to tackle complex, large-scale projects with both accuracy and efficiency. Whether it’s a challenging refurbishment or a brand-new fabrication, we’re here to support demanding industrial sectors with results that are both reliable and durable.

Our workshop is well-equipped for a variety of processes, including MIG, TIG, Subarc, and Flux Cored welding, along with rolling, guillotining, bending, and precision cutting of both mild and stainless steel. We handle everything from plasma cutting 30mm plates to gas cutting plates that are up to 125mm thick. Additionally, our in-house services encompass stress relieving, wet-spec paint application, and certified non-destructive testing (NDT) to ensure that every job meets the highest standards.

But we don’t stop at the workshop. A&G Price also offers responsive on-site services throughout Australia. Our skilled design engineers and mechanical fitters are ready to provide equipment inspections, repairs, and shutdown maintenance for industries like mining, energy, and cement production. We’re frequently called upon for major shutdown work and have earned the trust of leading names across various sectors.

Our mechanical fitting division is backed by over 140 years of industrial expertise. With heavy-duty workshop equipment, including 200-tonne presses and dual 10-tonne overhead cranes, we meticulously rebuild and repair mechanical systems. From rail and marine components to bearings and process plant equipment, we deliver customised solutions supported by a comprehensive archive of engineering drawings.

Our Fabrication Shop, spanning 1600m² and with a 20-tonne lifting capacity, supports a diverse range of welded fabrications. Equipped with specialist welders and tools, A&G Price manages both challenging repair and refurbishment projects as well as new fabrications.

Our range of services includes:

-

MIG

-

TIG

-

Subarc

-

Flux Cored

-

Mild Steel

-

Rolling to 25mm x 3000mm wide

-

Guillotine to 12mm x 3000mm wide

-

Bending to 16mm x 3000mm wide

-

Plasma cutting up to 30mm plate x 13 metres long

-

Stainless Steel

-

Gas cutting up to 125mm plate x 13 metres long

-

Stress Relieving

-

Wet Spec paint systems

-

In-house NDT

On-Site Services

We provide on-site services, including design engineers who visit sites to assess equipment for repair or replacement. Our mechanical fitters are engaged by companies like Golden Bay Cement, Newmont Waihi Gold, and Oceana Gold for maintenance shut-down work.

Please contact us for rates and availability.

Fittings, Repairs & Rebuilds

With over 140 years of experience, our team of skilled fitters handles a variety of mechanical equipment across industries including mining, rail, marine, hydro-electricity, and defence. We maintain a comprehensive library of equipment drawings for sectors such as cement, lime, fertiliser, steel, rock, and coal processing.

Our fitting shop includes:

-

Presses with a capacity of up to 200 tonnes

-

A specialised press for rail wheels and axles

-

2 x 10-tonne cranes

-

Capability to centrifugally cast a range of white metal bearings